Want a customized inspection in China?

6 times conversation normally

-The company receives your inspection order. For example, when they say they can do in all over China.

-Then they will send the order to another inspection company which is local to the inspection location.

-Then this second company will send the instructions to the real inspector.

-The inspector will visit the factory and check the goods.

And then they use the same routine to report it back to you.

Hire me

Take your words directly. Report to you directly.

* All cost will plus a 4.4% PayPal fee.

What is a video report for inspection?

How I do the inspection?

1. Collect Inspection Requirements

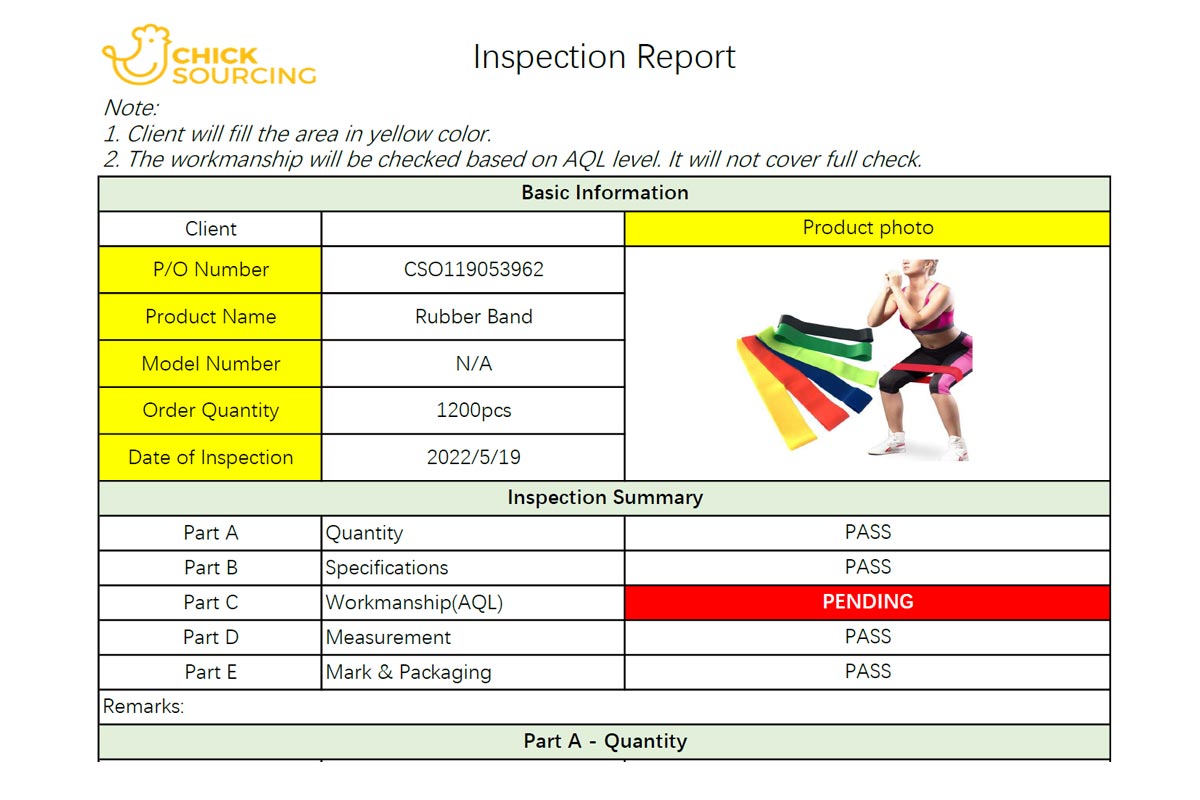

Before we start the inspection, we need to understand the basic information, the product and the inspection requirements. We use the form to collect relevant information. Basically, it will cover order information, and how to test the product. Please book the inspection before one week.

2. Confirm Inspection Sampling

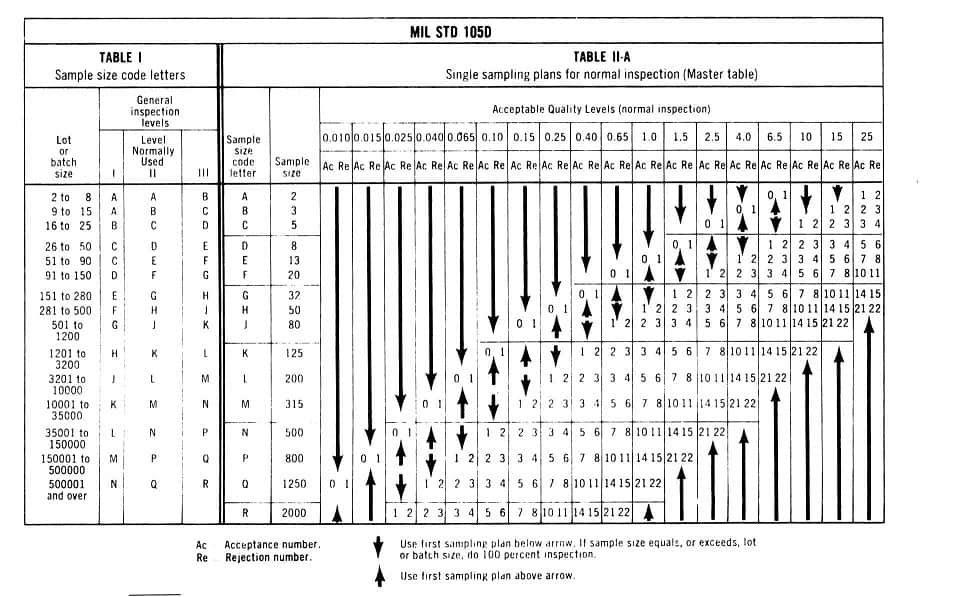

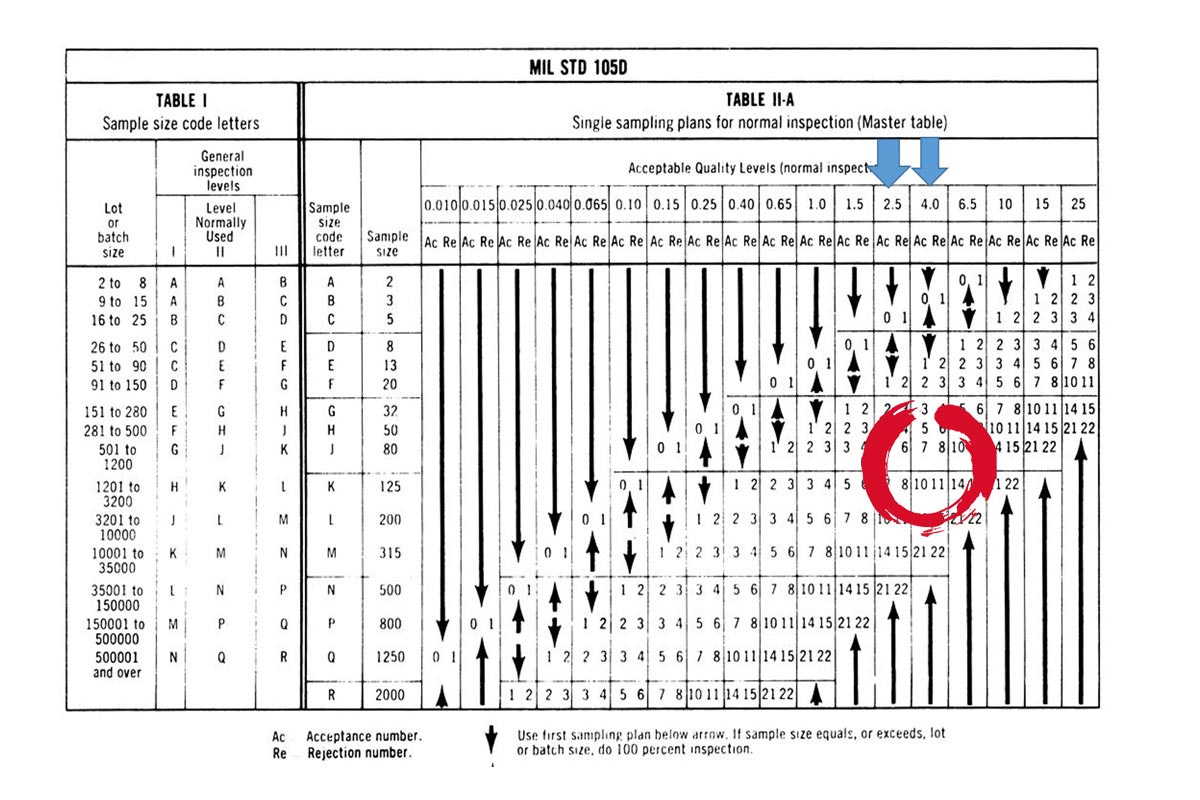

For a default sample standard, it is based on MIL-STD 1050D. The quality standard is Major 2.5, Minor 4.0

You can google the standard. Or I explain to you after you make the order.

3. Deliver Inspection Report Plus a Video

An inspection report will have PDF file which contains all necessary information with photos, and a video report to explain the details what happened in the factory.

All about quality control

Step A: What is an AQL quality standard?

AQL level means Acceptable quality limit. Wikipedia Link. For example, you may saw some company say their quality standard is AQL 0, 2.5, 4.0 It means it will allow 0 critical defectives, 2.5 major defectives, and 4 minor defectives. What is a critical, major and minor defective? Original article Link.

1. A Critical Defect

is one that is deemed to be hazardous or unsafe.

For example, a sharp point that may hurt you. Or the product is not manufactured correctly, it will hurt the user or someone.

2. A Major Defect

Is a function problem failure. For example, the phone cannot turn on. It will against the function of a phone. Other examples

-Holes and scratches

“They are common issues to deal with. Most suppliers in Asia have the mentality that these defects can be expected and are not serious. However, for the average importer, these defects could impede the products from being sold.”

-Size/Weight Discrepancies

Also common is for measurements to be off, sometimes by millimeters, other times even by inches. It is important to ensure that your inspector has knowledge to use proper measurement devices to ensure the most accurate measurement.

3. A minor defect

is a discrepancy from the standards, but it will not very likely to affect the function of a product.

For example, poor sewing

Untrimmed or long threads are the most common defects on textile inspection. These are basically minor defect, but it will still be a problem with the end user. So your textile products need to check these problems very seriously.

Step B: What is a Sampling Plan

MIL-STD-105 is a common international sampling plan, although different countries will have their own standard. Here is the sampling chart